01

Carbon steel moulds

Technical Design

Sheet metal molds custom-designed and optimized to minimize joints and welds, with careful attention to precision and the final part’s performance.

Laser Cutting and Milling

Depending on the geometry and specific requirements of the mold, we employ different technologies, including laser cutting and CNC milling. The parts are then welded to ensure structural and functional continuity.

Assembly

Each component is carefully inspected and positioned to prepare the structure for the subsequent stages.

Welding

Internal and external welds are finished by grinding to achieve surfaces that meet technical specifications.

Term Treatment

Heated to 700°C to stabilize the structure, reduce the risk of deformation, and enhance durability.

Finishing and Frame

The frame is designed according to the machine and the client’s requirements. Customized internal finishing and external painting complete the mold.

02

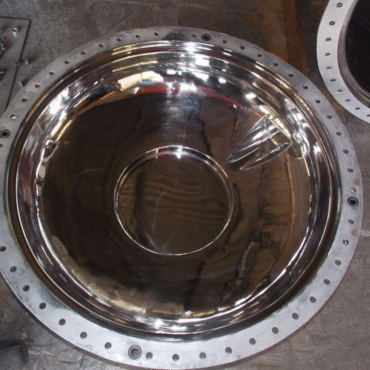

Molds in

stainless steel

Ideal for challenging environments or high temperatures. Stainless steel is primarily chosen for its corrosion resistance and compatibility with specific cooling methods.

03

Aluminium moulds

Ideal for plastic items requiring high aesthetic quality, complex shapes, and fine detailing.

The material allows for

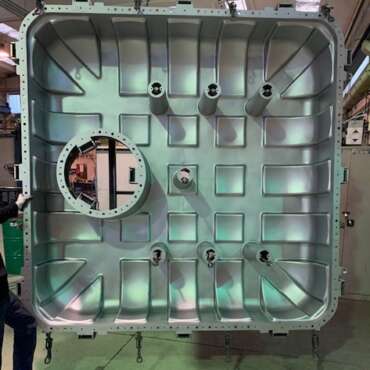

Cast Molds

Suitable for complex and large shapes. Starting from a precise model, the frame is designed for stability, compatibility with the equipment, and ease of use.

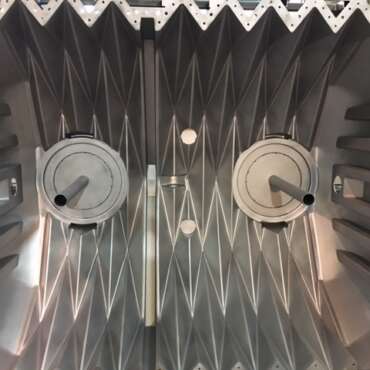

Milled from Solid Blocks

CNC-milled from solid blocks, these molds are suitable for products with tight tolerances and high-quality finishes. Ideal for technical or design-oriented items.

Beyond Rotational Molding:

Tailor-Made Metal Solutions

Alongside the production of molds for rotational molding, we offer manufacturing and services designed for cross-industry needs and high-complexity sectors.

Polyurethane Molds

We produce large molds for polyurethane, intended for high-performance sectors such as offshore and advanced marine solutions. We can also handle thicknesses over 3 mm to increase the strength and durability of the part.

Molding Support

- Customised jigs to maintain the part shape and minimize potential deformation during production.

- Technical assistance during molding upon request.

- Maintenance and repair of existing molds, subject to technical feasibility assessment.

Light Metalwork and Structures

- Design and fabrication of mold frames.

- Custom structures tailored to the client’s technical specifications.